Navigating the complexities of workplace safety can feel like a daunting task, especially when it comes to managing hazardous chemicals. Every business that uses, stores, or handles chemicals has a critical responsibility to ensure a safe environment for its employees and comply with strict regulatory standards set by organizations like the Occupational Safety and Health Administration (OSHA). A cornerstone of this responsibility is having a clear, accessible, and up-to-date chemical inventory.

Imagine the peace of mind knowing exactly what substances are present in your facility, where they are located, and how to respond in an emergency. This isn’t just a regulatory checkbox; it’s a fundamental aspect of proactive safety management. That’s why having a robust and easy-to-use osha chemical inventory list template isn’t just a convenience, it’s an absolute necessity for any organization committed to maintaining a secure and compliant workplace.

Understanding the Importance of a Chemical Inventory for OSHA Compliance

At its core, a chemical inventory serves as a comprehensive record of all hazardous chemicals present within your workplace. This isn’t merely about listing names; it’s about creating a living document that provides vital information for everyone, from new hires to emergency responders. Without a detailed inventory, it becomes incredibly difficult to implement effective hazard communication, plan for potential spills or exposures, or even conduct proper employee training.

OSHA’s Hazard Communication Standard (HCS) (29 CFR 1910.1200) explicitly requires employers to develop and implement a written hazard communication program. A crucial component of this program is an accurate list of hazardous chemicals known to be present in the workplace. This inventory is the bedrock upon which your entire hazard communication system is built, linking chemicals to their corresponding Safety Data Sheets (SDSs) and ensuring employees are informed about the risks they might encounter.

Beyond compliance, a well-maintained chemical inventory significantly enhances your facility’s safety posture. It allows you to identify potential chemical incompatibilities, pinpoint areas with high concentrations of hazardous materials, and streamline emergency response procedures. In the event of an incident, first responders can quickly access crucial information, potentially saving lives and mitigating damage. It also empowers your employees by giving them the knowledge they need to work safely and confidently around chemicals.

Key Elements Your Template Should Include

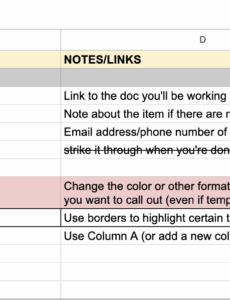

When you’re putting together your chemical inventory, whether from scratch or by adapting an existing osha chemical inventory list template, you’ll want to ensure it captures all the essential information. The more comprehensive your list, the more effective it will be for compliance and safety management. Here are the crucial details every entry should contain:

- Product Name: The exact name as it appears on the product label and SDS.

- Chemical Manufacturer/Supplier: The company that produced or supplied the chemical.

- Safety Data Sheet (SDS) Location: A clear reference to where the SDS for this specific chemical can be found (e.g., “Binder A, Section 3,” “Digital Folder: Flammables”).

- Physical Form: Indicate if the chemical is a liquid, gas, solid, or powder.

- Storage Location within the facility: Be specific (e.g., “Warehouse, Bay 3, Shelf 2,” “Lab 1, Fume Hood storage”).

- Estimated Quantity: An approximation of how much of the chemical is typically on hand.

- Hazard Classification: Briefly note the primary hazards (e.g., flammable, corrosive, toxic, irritant).

- Date of Inventory/Last Update: Essential for tracking the currency of your data.

Including these details ensures that anyone consulting the inventory has a complete picture, from understanding the substance itself to knowing where to find more detailed safety information. This level of detail transforms a simple list into a powerful safety and compliance tool.

Tips for Creating and Maintaining Your OSHA Chemical Inventory List Template

Creating your initial chemical inventory list can seem like a large undertaking, but approaching it systematically will make the process much smoother. Start by designating a specific individual or team responsible for this task. They should walk through your entire facility, meticulously identifying every container of hazardous chemicals. Don’t forget to check less obvious areas like cleaning supply closets, maintenance shops, and even administrative offices, as hazardous materials can be found in unexpected places.

Once you’ve identified all chemicals, carefully record the required information for each one, using your chosen template. Consistency is key here. Ensure that product names match their labels and SDSs exactly. For each chemical, immediately locate and cross-reference its Safety Data Sheet, making sure it’s readily available to all employees who might be exposed to that substance. Consider whether a digital or physical template best suits your operations, but ensure accessibility is prioritized.

However, simply creating the list is only the first step. Chemical inventories are dynamic documents that require ongoing maintenance to remain accurate and useful. Your facility’s chemical landscape is likely to change frequently as new products are introduced, old ones are phased out, or quantities fluctuate. Regular updates are non-negotiable for maintaining compliance and a safe workplace.

To keep your inventory accurate and effective over time, consider these practical tips:

- Conduct regular audits: Schedule quarterly or at least annual reviews of your entire chemical inventory to verify its accuracy against what’s physically present.

- Designate a responsible person or team: Assign clear ownership for updating and managing the inventory.

- Train employees: Ensure all relevant employees know how to access the inventory and understand its importance for their safety.

- Integrate new chemicals immediately: Establish a procedure to add any new chemicals to your inventory as soon as they arrive on site.

- Remove chemicals no longer in use: Update the inventory to reflect any chemicals that have been used up or properly disposed of.

- Ensure SDSs are readily available: Verify that a current Safety Data Sheet is accessible for every chemical listed on your inventory.

By implementing these maintenance practices, your chemical inventory transforms from a static list into a living, breathing safety resource. This ongoing commitment ensures that your workplace remains not only compliant with OSHA regulations but, more importantly, a consistently safe environment for everyone.

Adopting a comprehensive approach to chemical management, spearheaded by a detailed and regularly updated chemical inventory, provides invaluable benefits. It strengthens your overall safety program, minimizes risks, and fosters a culture of awareness among your workforce. Taking the time to properly catalog and manage your hazardous substances is an investment that pays dividends in both regulatory compliance and the well-being of your employees.

Ultimately, a robust chemical inventory is more than just a list; it’s a foundational element of a responsible and proactive safety strategy. It empowers your team with critical information, enables swift and effective emergency response, and demonstrates your unwavering commitment to a safe working environment for all. Start building or refining your inventory today and take a significant step towards a safer, more compliant future.