Embarking on any construction project, whether it is a small home renovation or a large commercial build, involves a myriad of details. One of the most critical aspects, often underestimated, is managing the materials required. Without a clear and comprehensive plan, you risk costly delays, budget overruns, and frustrating miscommunications. Imagine arriving on site only to find a crucial component missing, bringing the entire operation to a halt. This scenario is all too common when material planning is haphazard.

This is precisely where a well-structured material list template for construction becomes an indispensable tool. It transforms what could be a chaotic process into a streamlined, organized workflow. By providing a standardized format, it ensures that every necessary item, from the smallest screw to the largest structural beam, is accounted for. It is not just about listing items; it is about strategic planning that impacts every stage of your project, from procurement to final installation, ultimately saving you time, money, and headaches.

Why a Solid Material List Template is Your Project’s Best Friend

A robust material list template serves as the backbone of efficient project management in construction. Its primary function is to prevent common pitfalls like over-ordering materials that sit unused, or worse, under-ordering vital components that bring work to a grinding halt. By clearly outlining every item, its quantity, and specifications, you gain unparalleled control over your budget. You can accurately estimate costs upfront, negotiate better deals with suppliers based on precise requirements, and track expenses as they occur, ensuring your project stays within financial boundaries. This level of foresight is invaluable for maintaining profitability and avoiding unexpected financial surprises.

Beyond just financial control, a well-prepared material list template significantly improves communication across your entire team and with external stakeholders. When everyone is working from the same detailed document, there is less room for error or misunderstanding. Suppliers receive clear orders, reducing incorrect deliveries. Project managers can easily track progress and material availability. On-site teams know exactly what materials they need and when, allowing them to schedule their work more effectively. This collaborative benefit fosters a more harmonious and productive work environment, where everyone is aligned towards the common goal.

Furthermore, a template brings a level of consistency and professionalism to your project planning that is often difficult to achieve otherwise. It instills best practices, ensuring that no critical detail is overlooked, regardless of the project’s scale or complexity. This standardized approach means that even if team members change, the core system for material management remains intact, allowing for smooth transitions and continued efficiency. It effectively transforms a complex task into a repeatable process, increasing reliability and reducing the learning curve for new team members.

Think of it as your project’s navigational chart. Without it, you are sailing blind. With it, you can navigate the choppy waters of construction with confidence, knowing exactly what materials are needed, where they are coming from, and when they will arrive. This foresight empowers you to make proactive decisions, mitigate risks before they escalate, and keep your project moving forward smoothly towards a successful completion. It’s an investment in clarity and control that pays dividends throughout the entire construction lifecycle.

Key Components of an Effective Material List Template

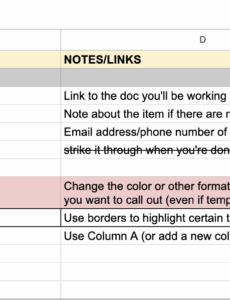

- Item Number: For easy referencing and tracking.

- Description: Clear and specific details of each material.

- Unit of Measure: How the material is quantified (e.g., linear feet, square meters, each).

- Quantity Needed: Precise amount required for the project.

- Unit Cost: The cost per unit of the material.

- Total Cost: Calculated by quantity multiplied by unit cost.

- Supplier: Name of the vendor providing the material.

- Delivery Date: Expected arrival date on site.

- Notes/Remarks: Any special instructions, specifications, or considerations.

These elements collectively provide a holistic view of your material needs, enabling meticulous planning and execution.

Customizing and Implementing Your Material List Template

Once you recognize the immense value of a material list template, the next step is to tailor it to your specific operational needs and project types. Generic templates are a good starting point, but true efficiency comes from customization. Consider the unique demands of your projects. Are you primarily involved in residential renovations, requiring detailed finishes and smaller quantities of diverse items? Or do you specialize in large-scale commercial builds where bulk ordering and structural components dominate? Your template should evolve to reflect these nuances, perhaps including columns for specific building codes or specialized equipment if applicable.

The format you choose for your material list template for construction also plays a significant role in its usability. While a simple spreadsheet application like Excel or Google Sheets offers a flexible and accessible starting point for many, specialized construction management software might be more appropriate for larger firms or complex projects. These dedicated platforms often integrate material lists with other project management functions like scheduling, budgeting, and inventory tracking, providing a more comprehensive solution. Evaluate your team’s tech proficiency and the scope of your projects when making this decision.

Effective implementation goes beyond just filling in the blanks. It requires a collaborative effort from your entire team. Procurement managers will use it for ordering, site supervisors for inventory checks, and project managers for budget tracking. Therefore, it is crucial to establish clear guidelines for how the template should be used, who is responsible for updating specific sections, and how information is shared. Regular training sessions can ensure everyone understands its importance and how to contribute effectively, fostering a culture of accurate and timely data entry.

Furthermore, your material list should not be a static document. Construction projects are dynamic, and changes can occur rapidly. Weather delays, design modifications, or supplier issues can all impact material requirements. It is essential to treat your material list as a living document, subject to regular reviews and updates. Implement a process for version control and ensure that any changes are communicated promptly to all relevant parties. This proactive approach ensures that your material list remains an accurate and reliable guide throughout the project’s lifecycle, reflecting the current state of affairs and preventing costly errors down the line.

Mastering the use of a material list template for construction is not merely about ticking boxes; it is about building a foundation for successful project delivery. By adopting a systematic approach to material management, you equip your team with the tools to navigate complexities, control costs, and maintain schedules with confidence. This strategic planning ultimately contributes to higher quality outcomes, happier clients, and a more robust reputation for your construction business.

Embracing this methodical approach to material planning transforms potential chaos into predictable progress. It ensures every nail, every beam, and every finish is accounted for, allowing your construction projects to run smoother, more efficiently, and within budget. This level of foresight and organization is truly the cornerstone of successful project execution in the modern construction landscape.